Delivery policy

Delivery policy

We deliver all parcels quickly via DPD courier.

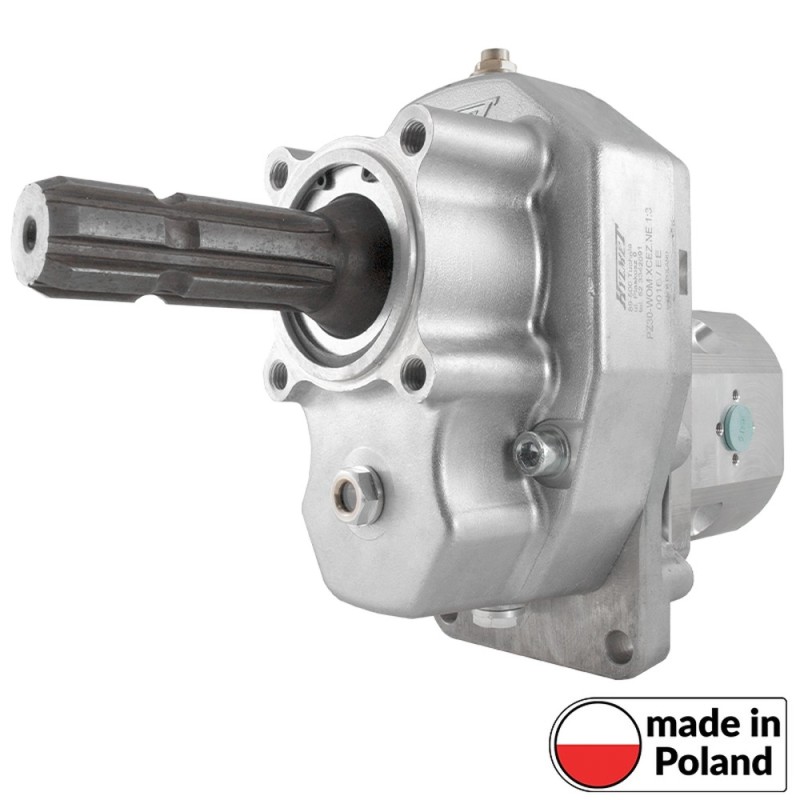

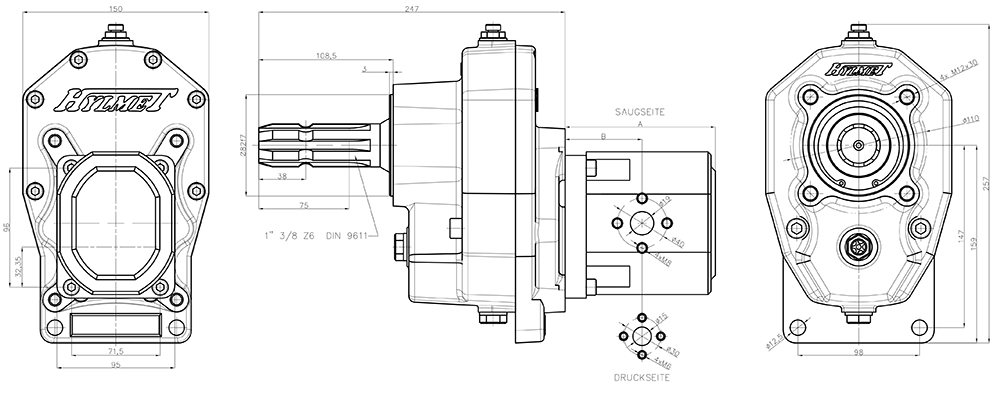

PTO shaft 1" 3/8, z6 DIN9611

| Ratio | 1:3.0 at 540 U | 1:2.0 at 1000 U |

| Power transferred | 30 kW | 35 kW |

| Input | 540 rpm | 1000 rpm |

| Output | 1620 rpm | 2000 rpm |

The gearbox is delivered filled with a high-quality synthetic gear oil.

So you no longer need to buy any transmission oil.

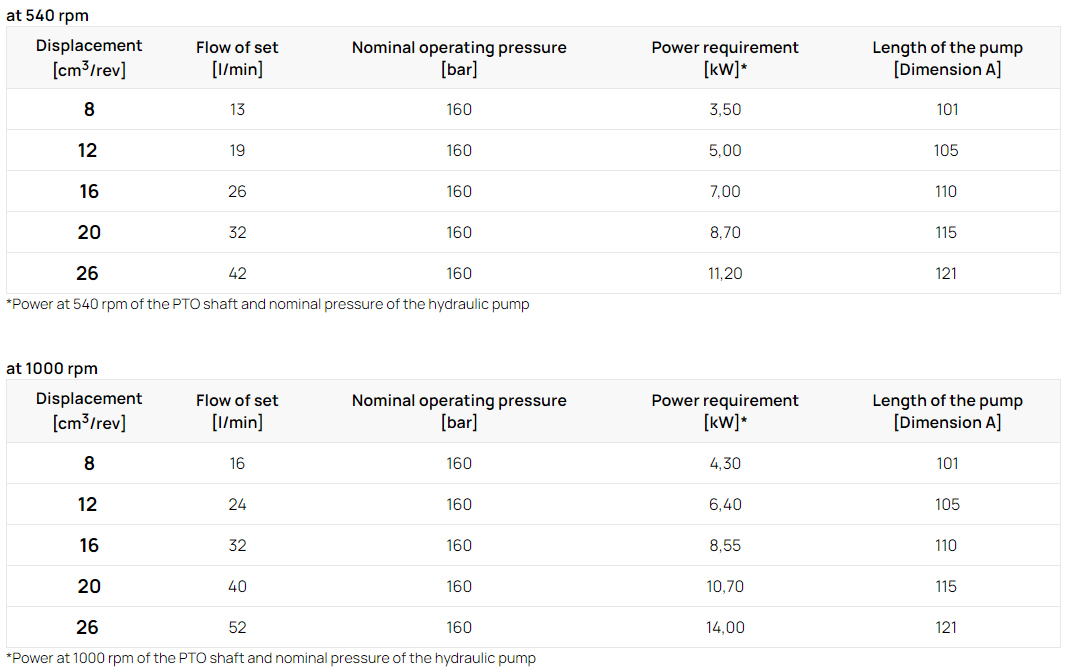

Displacement selectable from 8 - 26 cm3/rev

con. Wave 1:8

Direction of rotation right

operating pressure up to 160 bar

Inlet port: LK30-1/2"

Outlet port: LK40-3/4"

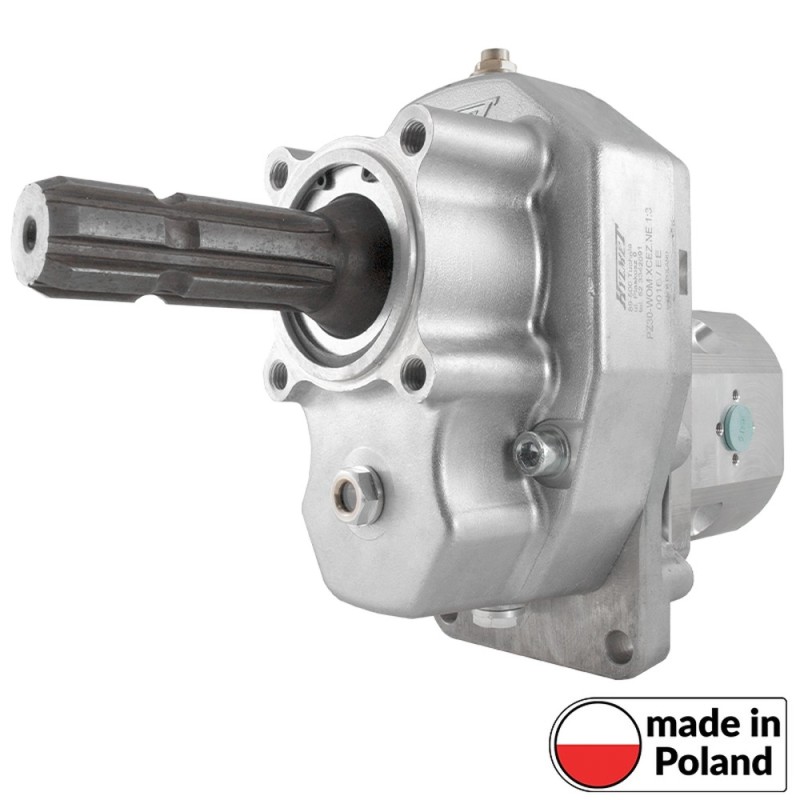

Our pumps and gearboxes are not Chinese goods. A product of 100% Polish manufacture. ***

Durable, trouble-free gearbox you can rely on for years. A product of 100% Polish manufacture.

Helical gearbox that guarantees quiet and comfortable operation (-15dB) and high transmitted power (+50%*).

The HYLMET gear drives are ideal for heavy duty applications thanks to their thick, robust housing (minimum thickness 7 mm) and up to 7 bearings.

The multiplier has standard mounting holes around the latch as well as two additional holes, eliminating the need to attach additional accessories such as a drive pinion.

* compared to Chinese "Italian" transmissions with a ratio of 1:3.8 max. 20 kW.

- Designed for continuous operation under high loads.

- Higher efficiency - the volumetric efficiency of the new generation of pumps is about 2-5% higher than that of the "classic"

- Fewer components - the new pump design reduces the number of parts. This is possible thanks to the introduction of a technology with much higher manufacturing accuracy both in housings and covers and, above all, in gears (Class VI gearing). As a result, the pumps achieve a longer service life with lower weight.

- Smaller pump dimensions - the new generation pumps are about 15% shorter in the direction of the wheel axle. At the same time, they retain the same performance as the " classic " construction.

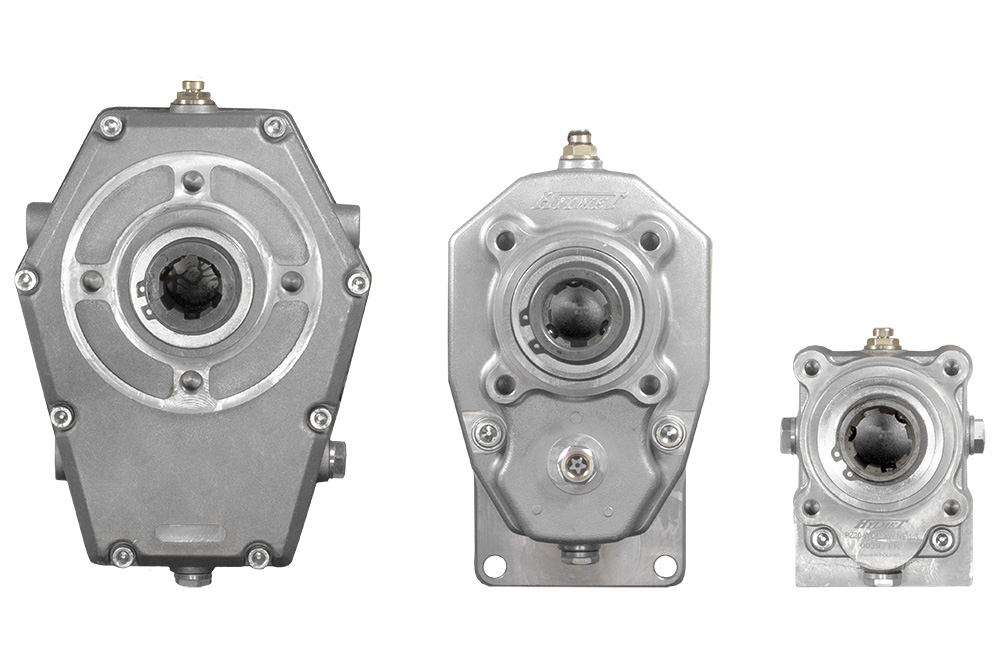

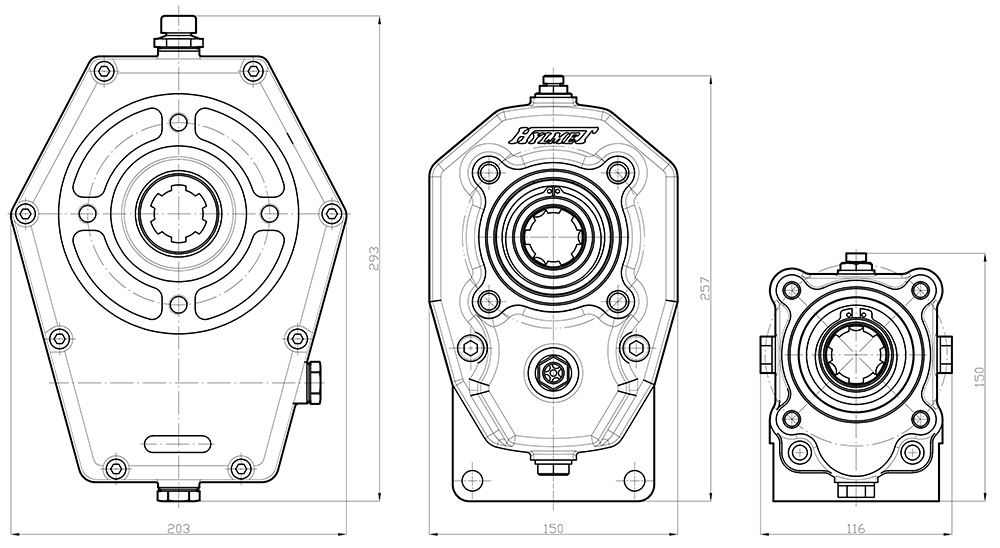

Gearbox comparison: